The manufacturing industry is not what it used to be!

Today, the manufacturing industry runs on speed, accuracy, and innovation, where even a little delay or design error can cost millions.

You must have encountered these situations: Difficulty explaining complex machinery to a client or wishing there was an easier and faster way to align your team on a new product.

If yes, this is where you feel the absolute need for 3D animation for manufacturing.

Here is the hard reality – Manufacturers still use traditional methods, such as shooting products or machines, due to budget limitations, ultimately creating longer lead times.

In fact, a report from Deloitte states that 86% of manufacturers want to adopt real-time 3D animation but need help understanding it.

Technical 3D animation easily fills that gap by simplifying complicated operations and helping even non-technical stakeholders get on board without any difficulty.

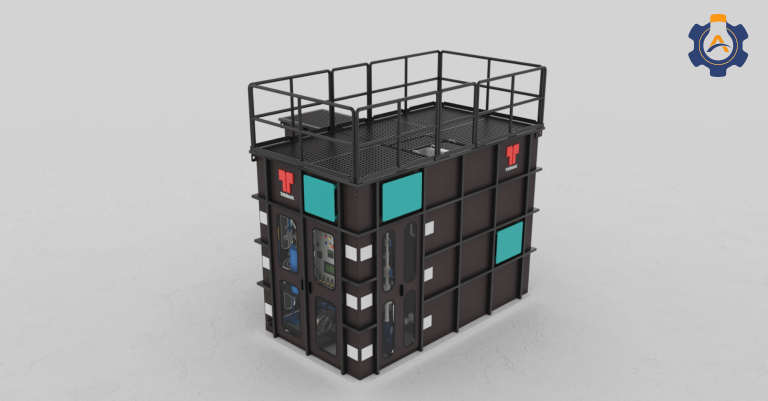

Here is the catch, industrial 3D animation solves real manufacturing pain points. From visualizing processes that would otherwise require expensive prototypes to creating training materials for workers- 3D visualization cuts through the clashes and gets things done.

Manufacturing industry advancements are reshaping the industry and are offering opportunities for growth, creativity, and enhanced sustainability.

How does 3D animation improve product design and testing?

The evolution of product visualization through animated content saw a significant shift from photographs to today’s sophisticated modeling techniques! All thanks to the development of 3D simulations.

1) Early visualization of product design & development

3D animations make it easy for manufacturers to visualize prototypes before physical prototype production begins.

Prototyping will allow teams to test functionalities, recognize design flaws, and make necessary adjustments in the early development phase.

By simulating how products will operate in real-world scenarios, manufacturers can optimize their development cycles and minimize costs related to physical prototyping.

2) Early prototyping = Quick verification of product

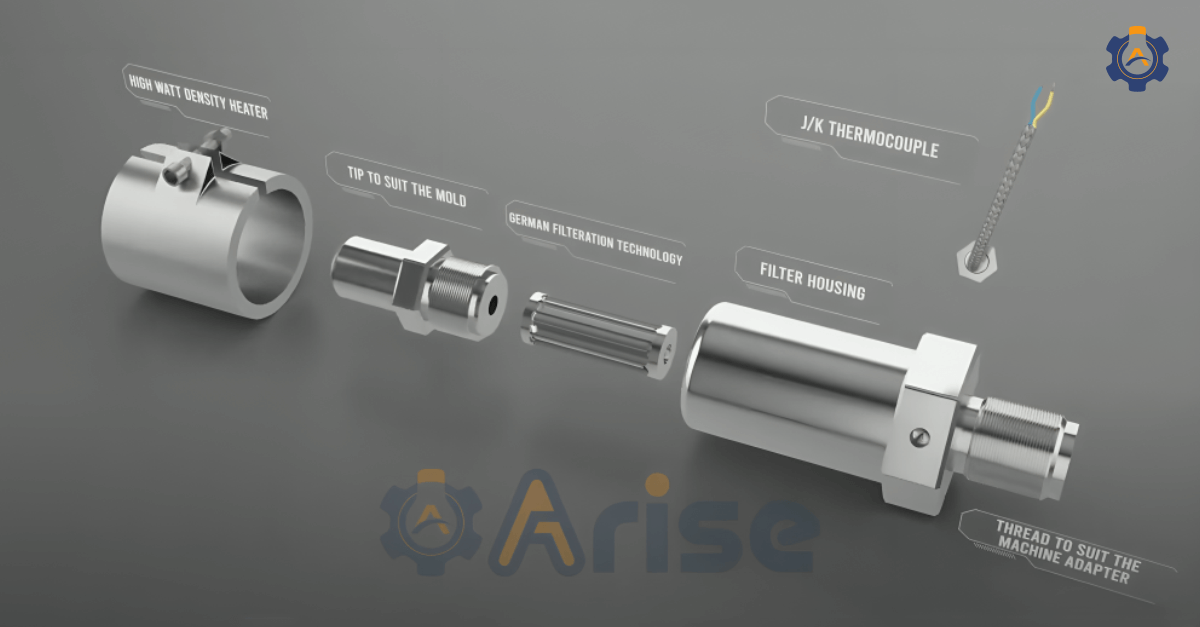

Utilizing 3D animations for prototyping automatically simplifies the process of verifying (testing) a product’s design against specifications.

Manufacturers can create virtual models that accurately represent how parts will move, rotate, or assemble, and engineers can identify points of friction, binding, or misalignment right at the early stage.

Furthermore, the virtual models also guarantee that all the parts fit together with the necessary tolerances. Even if only one part is slightly off, the system will immediately catch the issue, minimizing the chance of costly redesigns later.

Since all testing is done digitally, the materials for prototypes will not need to be discarded, and trial-and-error production will not be necessary.

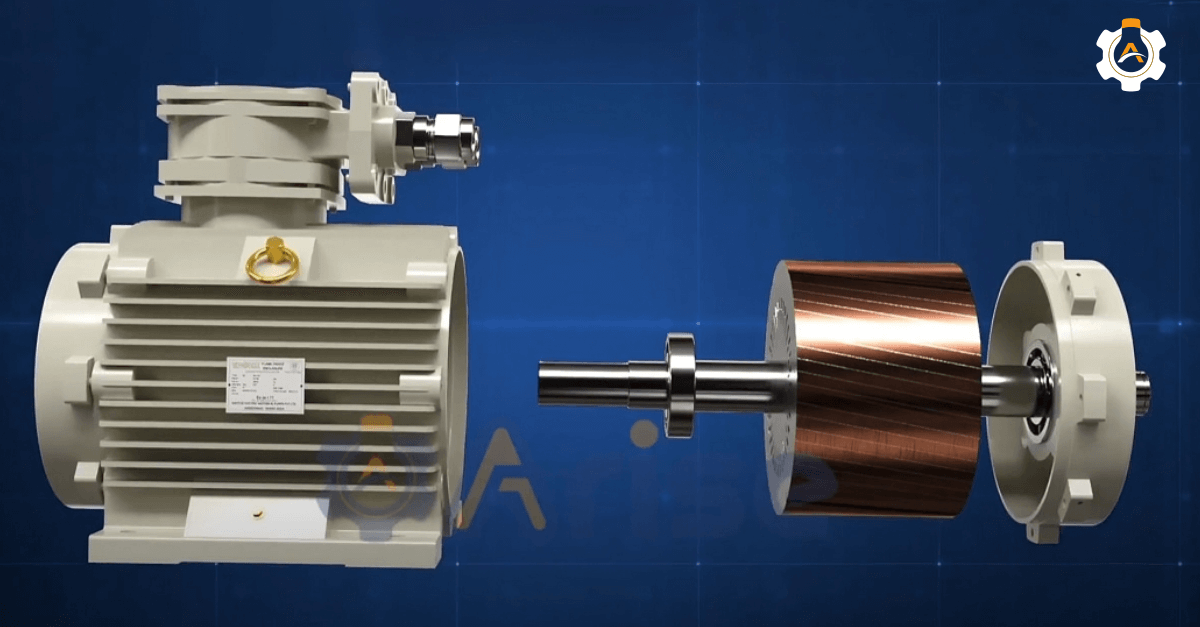

Large or complex machines (like turbines or industrial tools) often require custom tooling for each prototype, which can now be easily conducted with the help of 3D simulation.

3) Minimizing the design revisions

With 3D modeling in industrial design, it is easy to conduct quick tests of various configurations and make changes without physically rebuilding components.

This approach accelerates the design process and offers the flexibility to experiment with different material choices, colors, and functions at minimal cost.

Animation for prototype development ensures the product is optimized before it reaches production.

4) Effective communication & collaboration

Often, the question arises, how does 3D animation enhance communication in manufacturing?

3D animation in product design will allow marketing, engineering, and sales departments to see product designs in motion, making it easier to collaborate, communicate, and share ideas more effectively across teams.

5) Faster product launches

Technical 3D animation for the manufacturing industry is the technology that brings products to the market 3 times faster. Where producing physical prototypes takes time and money both.

However, when we talk about the benefits of 3D animation for product design, the best thing that stands out is its ability to run stress tests and performance simulations virtually. This eliminates the need for repeated physical builds and thus promotes the product in the market faster.

How are animations used for product demos, trade shows, and customer presentations to showcase innovative product design?

So, when was the last time a static product image truly amazed you? The reality is today, businesses need that extra punch to stand out. That’s where 3D animations come in.

Did you know that viewers retain 95% of a message when watching content in video format, compared to only 10% when reading text or viewing an image? Pretty mind-blowing, right?

1) Impact on trade shows

You are all crowded at the trade show, and you notice your competitor has a physical display of the product. But you?

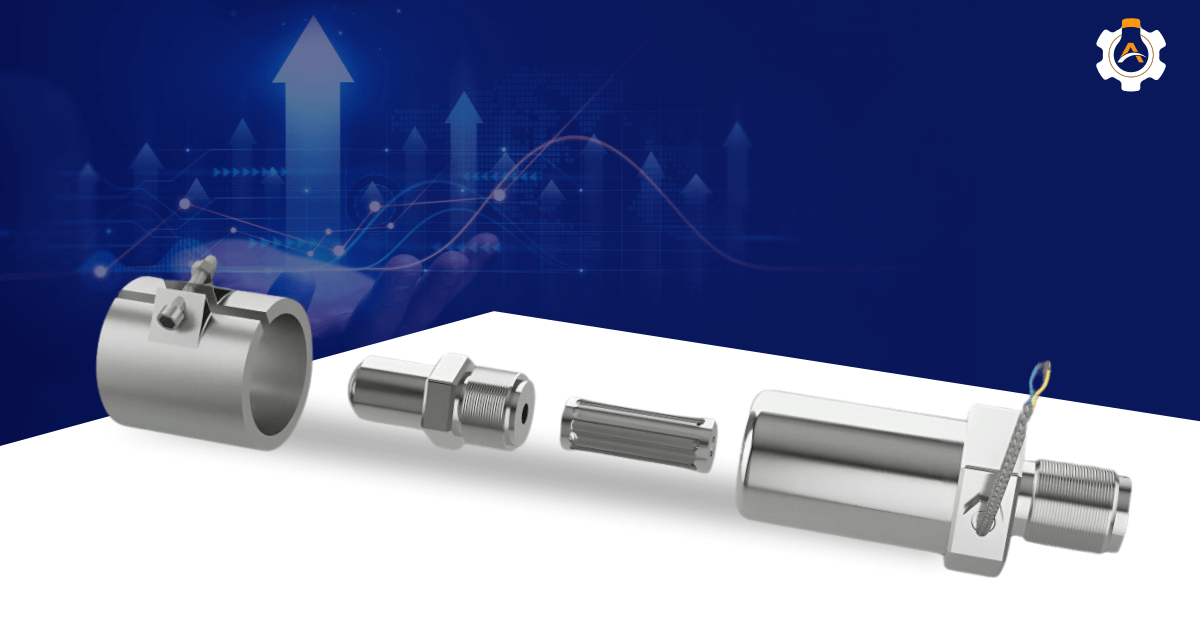

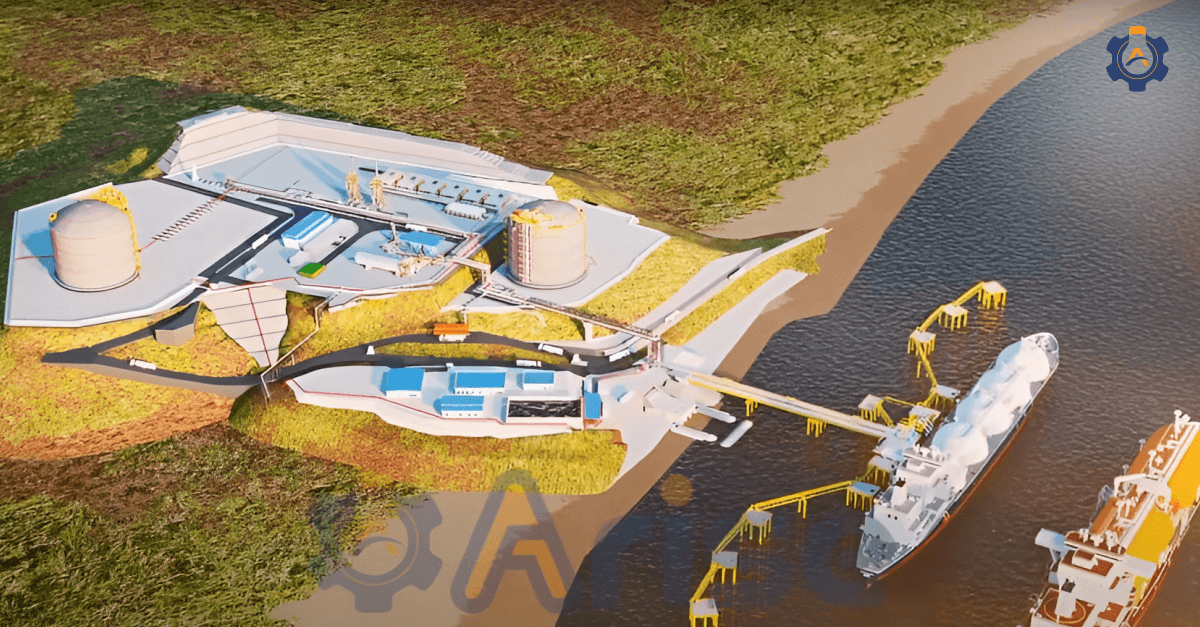

You’ve got an impressive 3D animation showing your machinery/technical product/industrial equipment in action. This animation highlights all the features and benefits while revealing every remarkable detail.

Who do you think is getting all the attention here? Of course, you!

The best part is that you don’t need to take heavy industrial equipment or machinery with you everywhere. Your entire product line fits on a USB drive.

2) The impact on customer presentations

Gone are the days of those PowerPoint slides. With 3D animations, you can:

Show your product working in real-time

Highlight features that usually cannot be seen in static images

Demonstrate complex processes in simple ways (The best part of adopting manufacturing visualization)

Letting customers virtually “touch” and interact with your product

Companies using 3D animations in presentations report 40% higher engagement rates. Why? Because people love seeing how things work!

3) Impact on a product demo

Forget about those days of “imagine this” or “picture that.” Now you can directly show:

Excellent USP’s of your product

Cross-sections in motion

Assembly sequences

Maintenance procedures

Think about it – When a customer can see exactly how your product solves their problem, isn’t that half the battle won? Definitely yes. One of the best marketing benefits of 3D animation.

How does 3D animation improve manufacturing by fostering remote communication and collaboration among teams?

3D animations foster remote communication and collaboration by simplifying complex product designs into engaging, easy-to-understand visuals that easily bridge the gap between geographically dispersed teams.

Relying on static PDFs or lengthy emails with 3D animations is no longer necessary.

Process efficiency through animation allows teams to interact with dynamic models in real-time, ensuring that everyone—engineers, marketers, or stakeholders—works from the same visual reference of the product.

Such 3D visualization simulates product behavior, enabling teams to find design flaws early, providing cost-effective manufacturing solutions, and speeding up decision-making.

Manufacturing efficiency through 3D product animation comes with a shared visual language that improves alignment, encourages meaningful feedback, and ensures smooth communication regardless of the locations of involved members.

What role does 3D animation play in manufacturing employee training that guarantees safe, interactive environments?

3D animations provide a safe, interactive environment for employee training by replicating real-world scenarios that clearly involve process simulation, and 3D product modeling will not let employees experience any actual risks and yet understand what is happening and how.

Real-time simulation in manufacturing, such as – Operating heavy machinery or practicing emergency protocols, can help employees gain hands-on experience in virtual environments by minimizing accidents and costly errors.

Enhanced manufacturing processes will engage learners through immersive experiences, leading to high retention rates that, in return, are more effective than traditional methods like manuals or live explanations.

Additionally, there might raise a question that how can 3D animation reduce costs in manufacturing? The answer is that 3D animations cut costs by minimizing the need for physical prototypes or machine downtime.

Remote access to training modules offers flexibility. It enables employees to practice anytime, anywhere, promoting continuous learning without disturbing daily operations. This clearly answers this question: Can 3D animation increase manufacturing efficiency?

This approach builds confidence and ensures that teams are fully prepared to respond to complex situations quickly & efficiently.

Conclusion

Today, where visual communication is essential, 3D animation is a revolutionary force.

Adopting this modern technology will eliminate challenges faced by traditional manufacturing processes by offering clear visual simulations for assembly lines, product prototypes, enhanced training with animation tools, etc.

This innovative approach will ultimately reshape the way the manufacturing industry operates.

So, get ready to experience the benefits of 3D animation in your business. Contact Arise Engineering Services and witness how our 3D animation services can help businesses restructure and modernize manufacturing processes.

FAQ’s

1) How is 3D animation used in the manufacturing industry?

3D animations help visualize product designs and production line layouts/complex processes before physical implementation, allowing design reviews and modifications.

2) Can 3D animation reduce errors in manufacturing?

Yes, 3D animation can minimize manufacturing errors by helping to recognize and fix design errors early in the process.

3) What types of manufacturing industries benefit from 3D animation?

Industrial

Automotive

Pharmaceutical

Oil & Gas

OEM’s

Energy & Power

Water & Waste Management

4) Is 3D animation cost-effective for small manufacturers?

Yes, it is, but again, it depends on the style, level of detail & size of the project & animation.