The manufacturing sector has been expecting something from Augmented Reality (AR) and Virtual Reality (VR) technologies.

These two advancements were promised to be game-changers, transforming how products are designed, communicated, and understood.

However, reality is not the same! Despite initial excitement, AR and VR have met many roadblocks.

Technological convenience is one of the most considerate issues.

The hardware required for these experiences can be expensive and inconvenient, leading to user discomfort and limited usability in high-speed manufacturing units.

Furthermore, developing high-quality, adaptable content is demanding, and many organizations need help in understanding the associated technologies.

As a result, manufacturers often face adoption challenges that restrict the practical application of AR and VR in their operations.

Despite all these challenges, Interactive 3D Models have emerged as an exciting and easy-to-use alternative.

The best part is that they provide a versatile, cost-effective solution that aligns more closely with manufacturers’ current needs.

The Reality Check – Why AR and VR Haven’t Hit the Mark

Why has their extensive approach been so slow?

Fact. Here, the core issue is not a lack of innovation but rather a mismatch between the current state of these technologies and the manufacturing industry’s practical needs.

AR and VR in Manufacturing – Expectations vs. Reality

AR and VR technologies in manufacturing promises ;

Expectations were,

Improved training

Excellent efficiency

Remote Collaboration

Increased precision

Faster time to market

Improved quality

Reduced costs

The reality in manufacturing has a different picture. Despite their potential, these technologies face a slow (very slow) path toward widespread adoption, hindered by several significant barriers;

Firstly, the technical complexity of AR and VR comes in as a major challenge. Executing these technologies requires a high level of expertise and solid investment, making them less accessible for many businesses.

Another considerate issue is the dependency on specific hardware. AR and VR technologies require headsets and other specialized devices that are costly and restrict the mobility and flexibility critical on the manufacturing floor.

Integration also presents an unavoidable challenge. AR and VR systems often struggle to smoothly mesh with existing product design and communication tools. This approach of AR & VR can disturb established workflows, leading to inefficiencies rather than the expected improvements!

The journey from expectation to reality is filled with challenges.

The Advantages of Interactive 3D Models in Product Communication

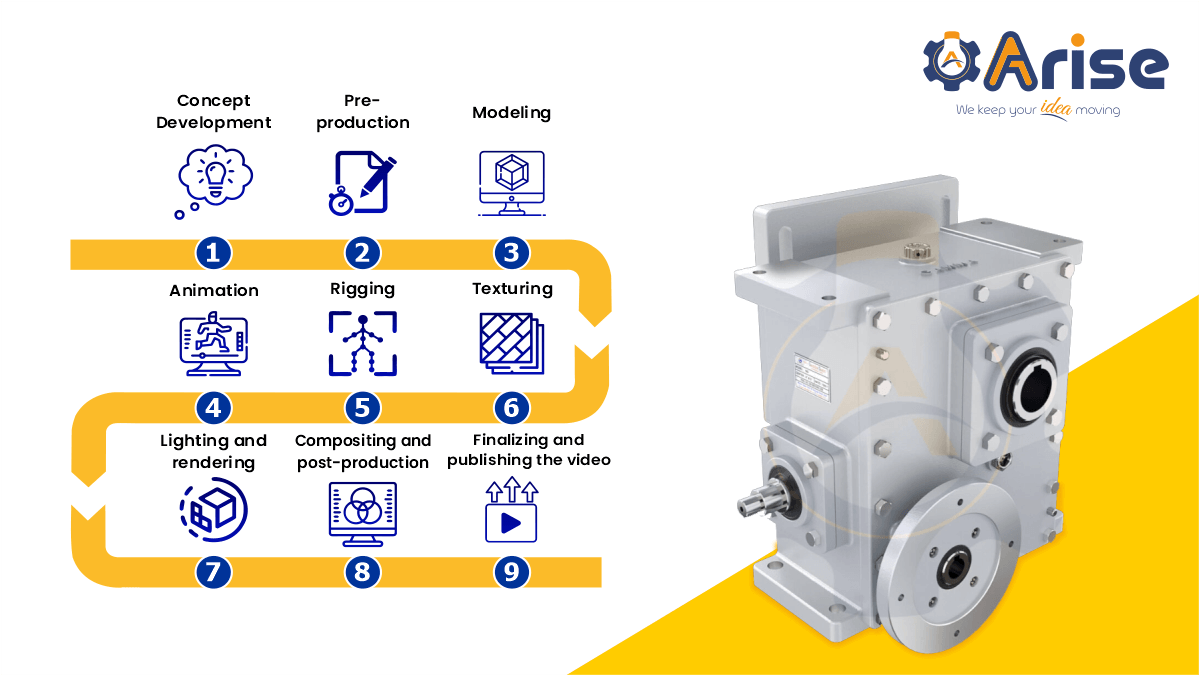

How we show and talk about products is rapidly shifting gears. The reason? The rise of interactive 3D models.

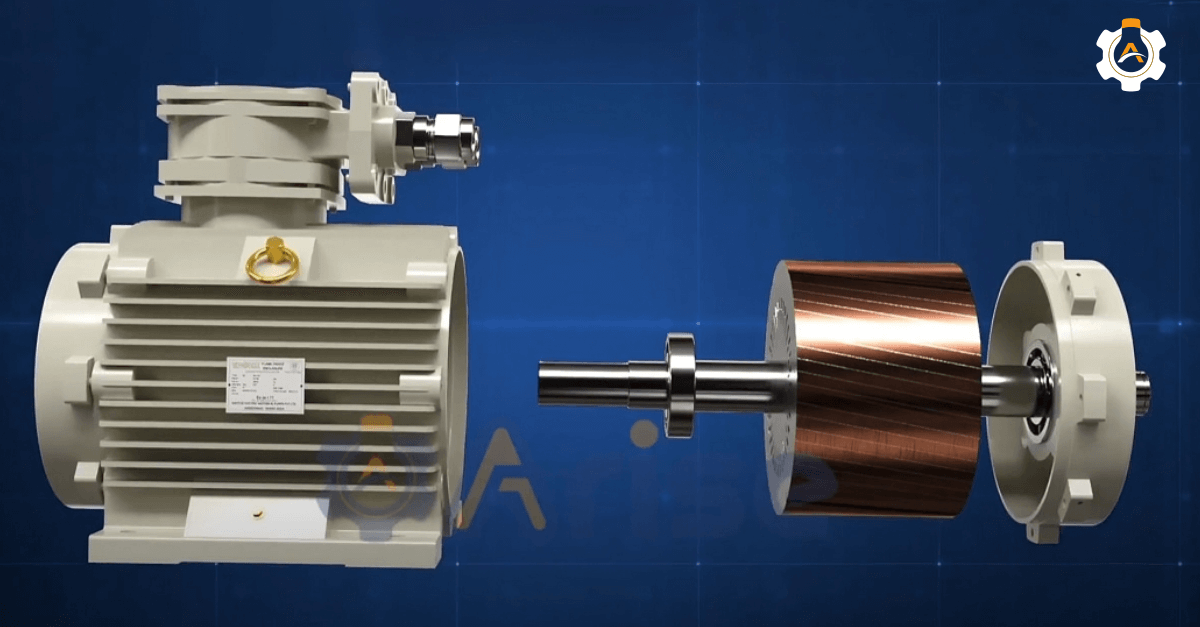

These models let you explore products from every angle with all the effectiveness.

1) Ease of Use

Interactive 3D product models are naturally user-friendly.

They allow users to interact directly with the product in a virtual environment.

This interactive experience automatically increases the understanding, as users can rotate the model, zoom in on details, and visualize complex components.

By facilitating intuitive product exploration, manufacturers can ensure that users get critical information quickly and effectively.

2) Cost Efficiency

Using interactive 3D communication tools can lead to high-cost savings.

All those traditional product communication methods involving heavy manual printing and distribution can be both time-consuming and costly.

At the same time, it is much easier to share 3D models digitally, removing the need for physical materials.

The best part? Interactive models can be reused across different platforms, reducing product updates and revision costs.

Additionally, the initial investment in creating high-quality interactive 3D models can reduce after-sales support costs directly.

3) Faster Implementation

The acceptance of interactive 3D models into existing systems is easy and rapid.

Modern software solutions allow for quick development and deployment of these models, allowing manufacturers to adjust quickly to market changes.

This agility is important in today’s speedy business environment, where the ability to respond to user’s needs and feedback can highly impact competitiveness.

How Interactive 3D Models Outperform AR and VR.

Interactive 3D models are a better choice than AR and VR for a few reasons. Let’s talk about them!

1) Better Flexibility

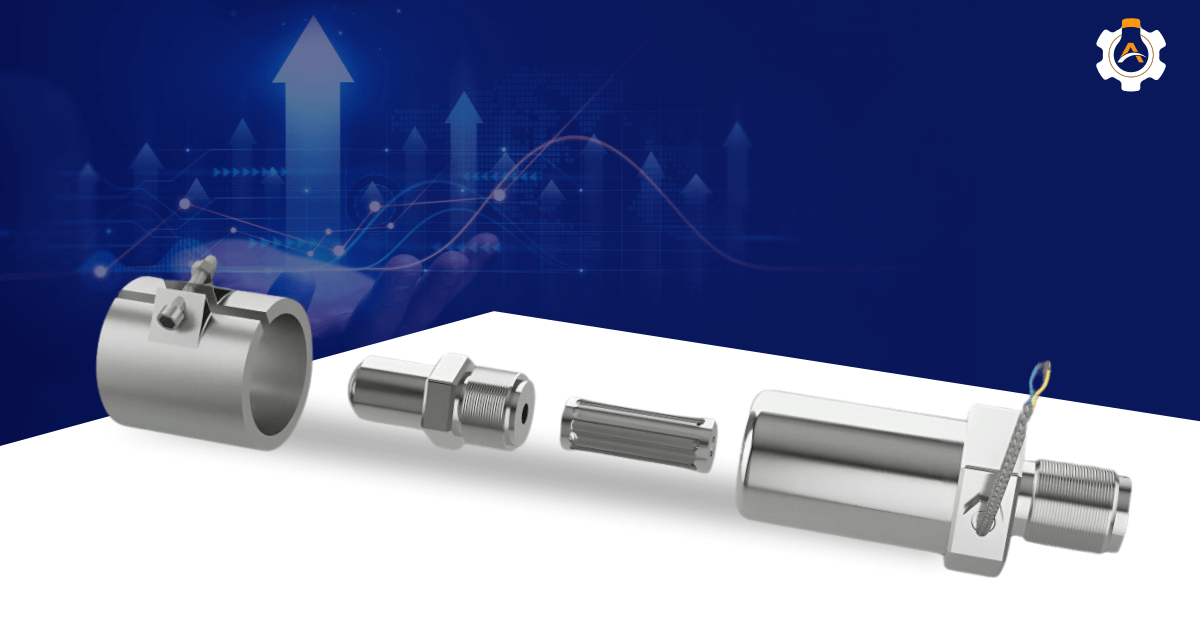

3D product visualization offers manufacturers excellent flexibility in showcasing their products effectively.

If we compare AR and VR, both of these technologies require specific hardware and can be challenging.

On the other hand, interactive models are accessible on various devices without any specialized equipment.

Manufacturers can easily modify 3D models to highlight changes in design, materials, or features, ensuring their presentations remain up-to-date and to the point.

2) Scalability

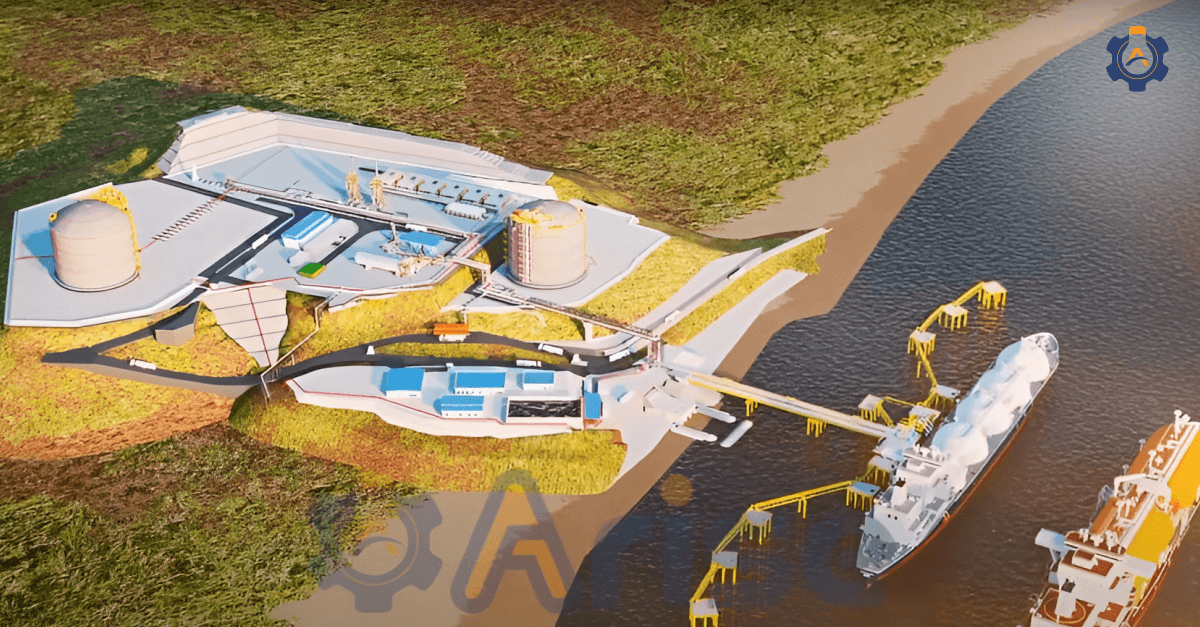

One of the most considerate features of 3D product visualization is its scalability.

As and when the product lines expand, it becomes necessary to apply more efficient methods to effectively present the products consistently.

Interactive models can be created and stored digitally, allowing quick updates and easy sharing across teams and stakeholders.

Companies can develop many different product versions without getting into physical prototypes, reducing the time and costs related to traditional manufacturing processes.

3) Enhanced Customer Engagement

Engagement in B2B industries cannot be compromised. Additionally, customer engagement with 3D models is a game changer.

Interactive 3D visualizations allow clients to discover products in a dynamic environment, giving them a clear understanding of the product’s features and benefits.

This level of interactivity will develop a deeper connection between the manufacturer and the customer, as clients can handle the model to see it from various angles, zoom in on details, and even simulate its functionality.

This brilliant experience is far more engaging than AR/VR experiences that may not be as intuitive or accessible.

Case study

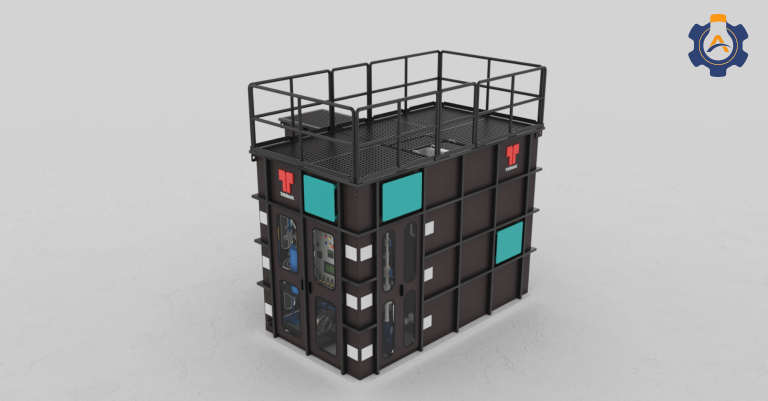

Product – Atom Thermax

Description

Get an interactive 360 view of Thermax.

We have created this excellent product in a virtual environment, giving it a 360-degree view.

The accessibility of this Thermax will let you explore the entire product from every angle. You can zoom in and out on details, just like you can do when you are present in person. Click on hotspots to access additional information.

Truly one-of-a-kind advancement for manufacturers.

Conclusion

Coming to an end, it’s clear that interactive 3D models are an excellent alternative to AR and VR for manufacturers.

From unmatched flexibility, easy updates, and modifications to being highly scalable, they exceptionally offer an interactive experience that takes the attention & consideration of potential users.

Don’t settle for less. With Arise Engineering Services, you can differentiate your product presentations and drive better business outcomes using 3D-interactive models. Now is the time, take action!