The manufacturing industry has continually progressed in innovation.

But what if we told you there’s a revolutionary tool quietly reshaping the environment from the design conception to factory floor execution? 3D modeling is that tool!

High-time, we should now forget about flat, two-dimensional blueprints.

As the renowned architect Frank Gehry once said, “Technology offers designers the freedom to imagine, visualize, and then realize their visions like never before.” You see the role of 3D modeling as holding the future in your hand.

So, get ready to witness how 3D modeling adds life to ideas, enhances processes, and ultimately leads to a future where manufacturing is productive and truly inspired.

What is 3D Modeling?

3D modeling is the process of creating a three-dimensional representation of any object or surface using specialized software.

Further, 3D modeling involves generating a digital model that can be manipulated and viewed from any angle in the real world but on a computer screen.

This digital model comprises points, lines, and shapes (usually triangles) that define the object’s form, size, and surface.

Role of 3D Modeling in the Manufacturing Industry

1) Design and Prototyping

3D modeling comprises creating detailed digital models to visualize and refine product designs before making physical prototypes.

2) Precision and Accuracy

3D modeling has a higher level of precision and accuracy that instantly reduces errors and enhances the overall quality of the final output.

3) Cost Efficiency

3D modeling reduces material waste and lowers production costs by identifying probable issues and optimizing designs before manufacturing starts.

4) Collaboration and Communication

The 3D model enhances collaboration between the entire project team. It also improves communication by providing a clear and detailed visual representation of the product, enabling better decision-making.

5) Customization and Personalization

3D modeling allows for easy customization of products to satisfy every specific needs and preferences of customers.

6) Simulation and Testing

The approach of 3D modeling involves virtual simulation and testing of products under various conditions, identifying potential issues, and improving performance before physical production.

7) Production Planning and Control

3D modeling also aids in efficient production planning and control by providing detailed models that guide the manufacturing process and give adherence to design specifications.

8) Quality Control

3D modeling, on the other hand, also supports quality control processes by offering precise models to compare against produced items, ensuring consistency and compliance with standards.

9) Documentation and Compliance

The 3D modeling method simplifies documentation and compliance by providing comprehensive records of designs, changes, and production processes, ensuring regulatory requirements are met.

Industries that Use 3D Modeling Services

| Industries that transformed using 3D Modeling |

| 1. 3D Modeling in Manufacturing |

| 2. 3D Modeling in Industrial design |

| 3. 3D Modeling in the Pharmaceutical Industry |

| 4. 3D Modeling in Architecture |

| 5. 3D Modeling in Engeenering |

| 6. 3D Modeling in the Automotive Industry |

| 7. 3D Modeling in Advertising & Marketing |

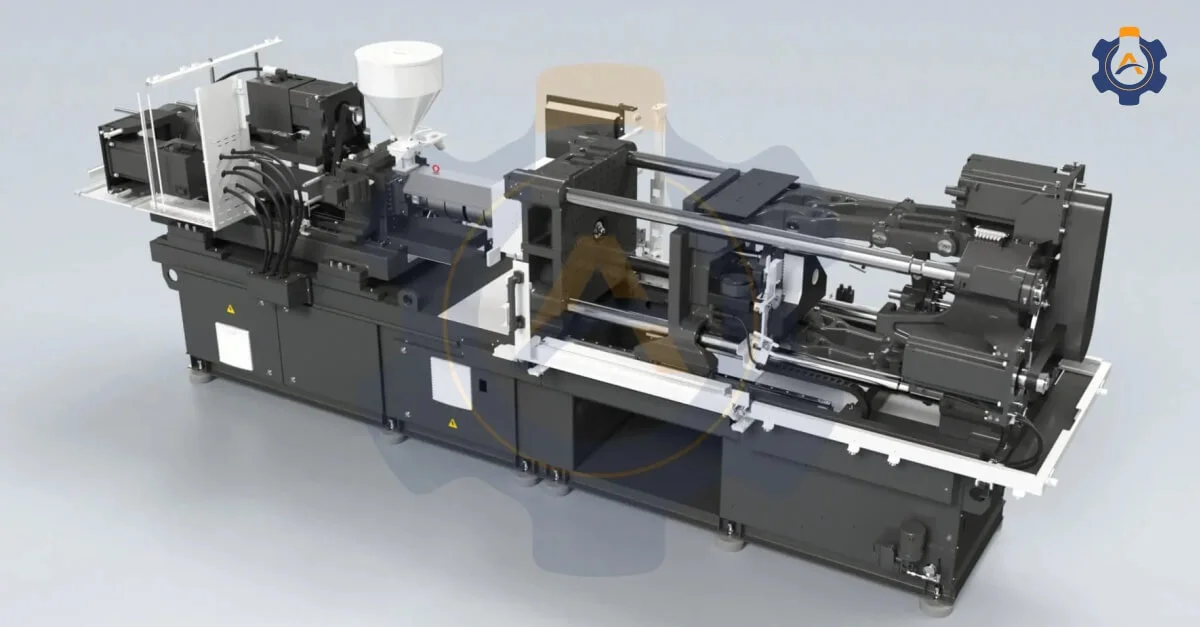

1) 3D Modeling in Manufacturing

3D models effectively reduces the development costs, identifies errors early, and lines up the whole process of production.

A study by Aberdeen Group found that companies using 3D modeling reduced product development time by an average of 36% .

Complex products can be virtually assembled using 3D models, helping recognize assembly challenges and develop error-free assembly lines.

2) 3D Modeling in Industrial Design

3D model will help designers visualize the final product, identify issues, and communicate the design effectively to clients, engineers, and manufacturers.

3D modeling, tweaking the design is as easy as a walk in the park. For instance, if the chair’s armrest seems too low in the 3D model, the designer can easily adjust its height and see the impact in real time.

3) 3D Modeling in the Pharmaceutical Industry

3D modeling designs complex medical devices like any surgical instrument. It allows for precise design, customization, and virtual testing to ensure functionality and patient safety.

4) 3D Modeling in Architecture

With 3D models, architects can create realistic visualizations of buildings before construction begins.

It helps develop a clear understanding of the intent of the design and refine plans before hitting the ground.

5) 3D Modeling in Engineering

The engineering industry is one of the early adopters of 3D modeling.

3D models can design and plan facilities like factories and power plants. This further facilitates efficient layout optimization and potential clash detection before construction begins.

Best part of a 3D model is that it will also let the existing physical objects be scanned and converted into 3D models for analysis, modification, or reproduction.

6) 3D Modeling in the Automotive Industry

3D models create accurate manufacturing instructions and plan assembly lines for excellent efficiency and fewer errors in production.

7) 3D Modeling in Advertising & Marketing

We all hear the word marketing 5 to 7 times daily, aren’t we? That’s because marketing is hugely important in business.

With marketing, companies could effectively market their products and raise awareness of what they are selling and why.

Before 3D modeling, the photographer would take a series of exceptional pictures of the company’s products, which would then be used in promotional material. This method was time-consuming and expensive.

3D modeling is fantastic for product catalogs and advertising media.

However, with 3D modeling, businesses can create marketing materials in less time and at a lower cost.

Conclusion

3D modeling has undeniably reshaped the manufacturing industry, emerging as a powerful tool that streamlines workflows, slashes costs, and ignites innovation.

Partner with Arise Engineering Services and experience the groundbreaking power of 3D modeling firsthand. Let’s revolutionize your manufacturing journey together.